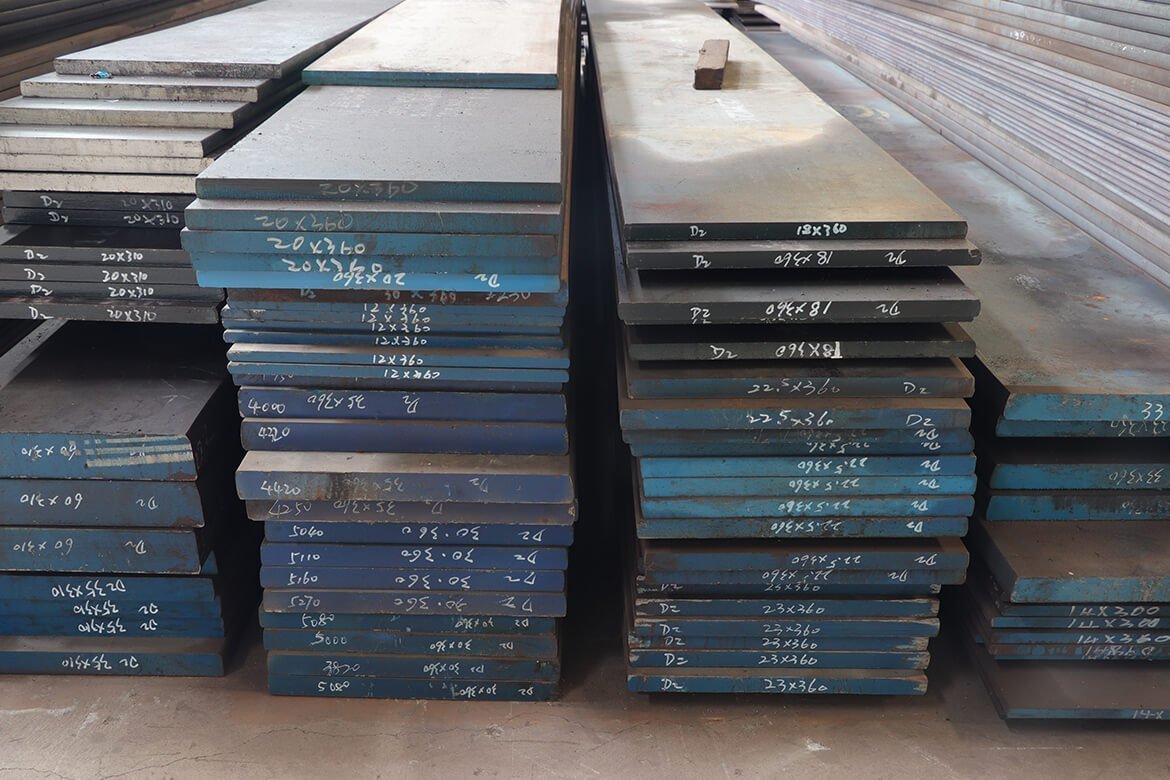

Our Products

AISI P20 / DIN 1.2311

AISI P20, also known as DIN 1.2311, is a popular pre-hardened tool steel grade commonly used in the manufacture of plastic injection molds and tooling applications. It is known for its excellent machinability, good wear resistance, and reliable performance in a variety of molding applications. Typically supplied in a pre-hardened state, it offers an optimal balance of hardness and toughness for tooling applications.

Steel Properties

AISI P20 is a micro-alloyed, high-quality steel that exhibits excellent machinability in the pre-hardened condition. It can be easily molded and polished to achieve high surface finishes, making it ideal for producing plastic molds that require intricate detail. It also demonstrates good wear resistance, toughness, and uniform hardness. Its composition allows for good through-hardening properties, along with moderate corrosion resistance. The steel is often vacuum-degassed to ensure that it has a minimal level of impurities, providing added reliability for tooling applications.

Application

AISI P20 is widely used for plastic molding applications, including manufacturing injection molds, blow molds, and compression molds. It is ideal for large and small mold dies in automotive and consumer goods industries, where precise detail and surface finish are required. Additionally, P20 is commonly used for producing die holders, insert molds, plastic molding tools, and die casting molds. Its ability to provide reliable performance at moderate temperatures, combined with its ease of machining and polishing, makes it a popular choice for tooling and die manufacturing.