Our Products

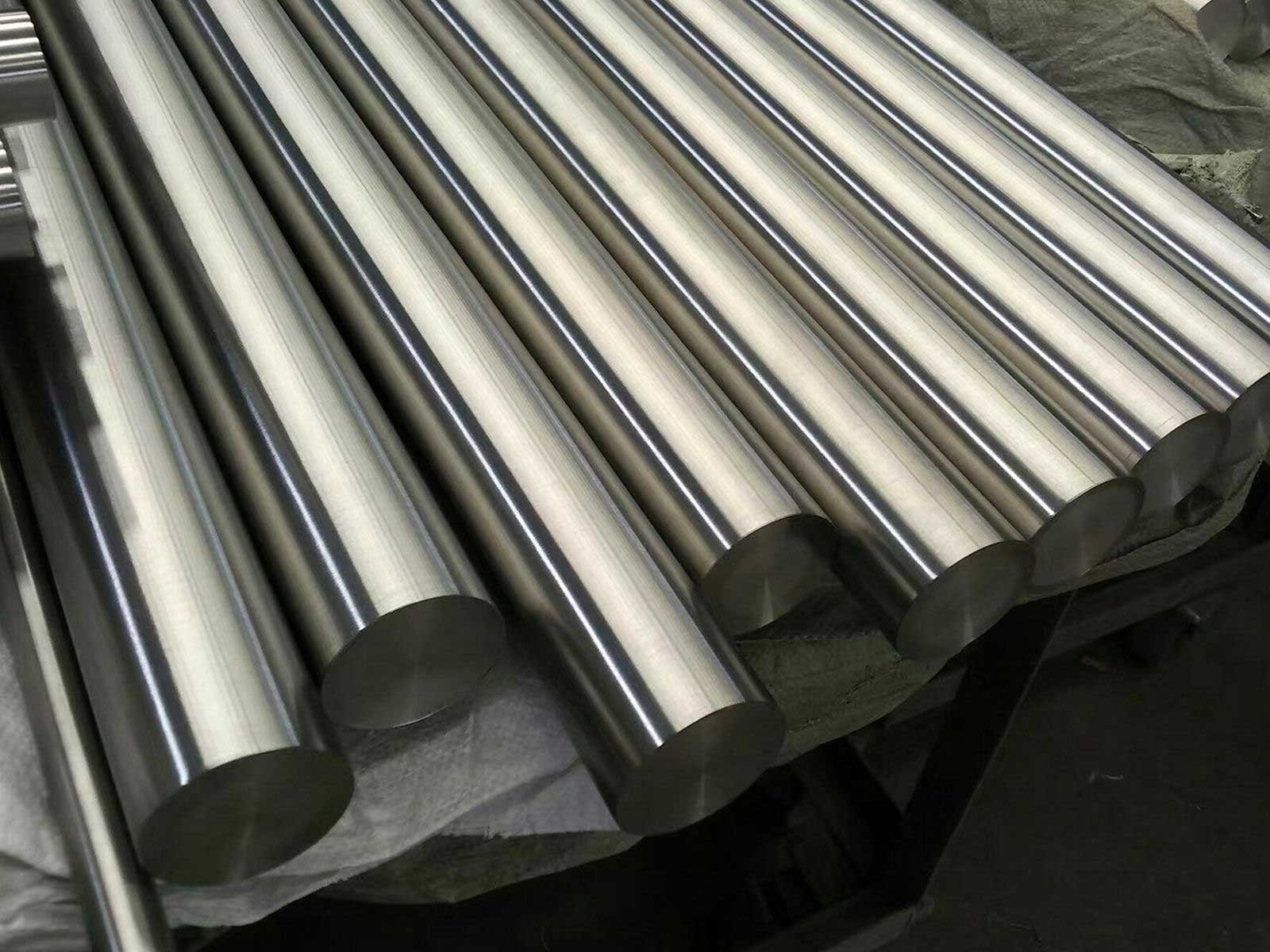

AISI DB6/ DIN 1.2714

AISI DB6 (also known as L6 / SKT4) is a hot work tool steel that is commonly supplied in a pre-hardened condition with a hardness range of 360-430 BHN. It is an upgraded version of DIN 2713, designed to provide improved performance for die applications. This steel grade offers better toughness, wear resistance, and overall die performance. The die blocks are supplied with additional forging reduction and upsetting, followed by double tempering to achieve superior ultrasonic quality.

Steel Properties

AISI DB6 / DIN 1.2714 is a special hot work pre-hardened steel known for its excellent toughness and high wear resistance. This steel is typically supplied in a hard, quenched, and tempered state, and can also be delivered in an annealed condition in special cases. With a working hardness range of 360-430 BHN, it offers good performance in high-demand applications. The enhanced alloy composition, including chromium (Cr), nickel (Ni), molybdenum (Mo), and vanadium (V), contributes to its exceptional wear resistance, toughness, and high hardness.

Application

AISI DB6 / DIN 1.2714 is widely used for producing dies and tooling components that require high toughness and wear resistance. Key applications include dies for drop forging hammers and mechanical presses, die molds, shoe blocks, die holders, cassettes, piston rods, cranks, shearing blades, and plastic molds. Its ability to withstand high stresses makes it particularly suitable for close die forgings, offering extra toughness and high hardness due to its high-grade alloy content. This steel is highly recommended for applications demanding durability and resistance to wear.