Our Products

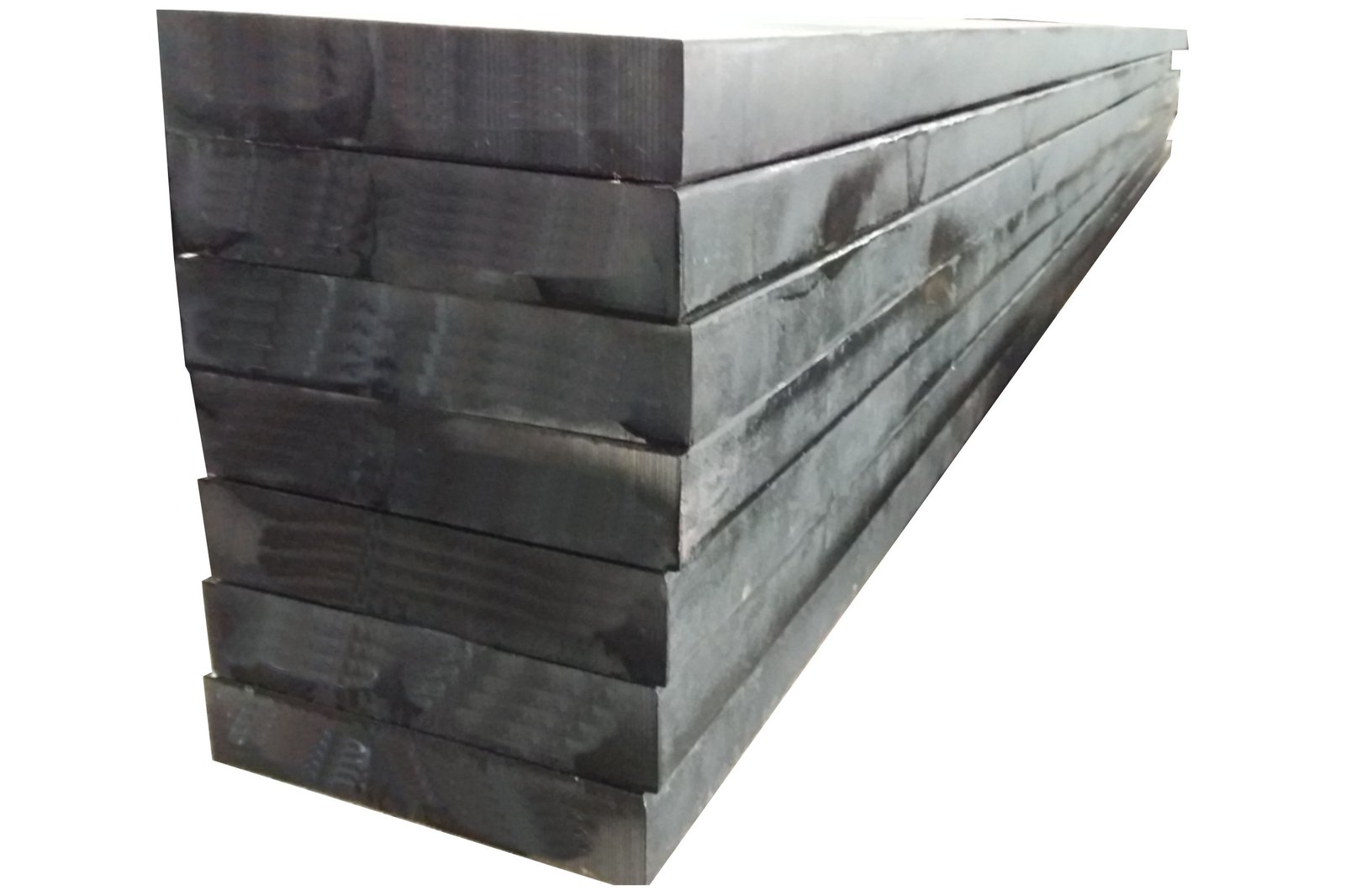

AISI HCHCR D3 / DIN 1.2080

D3 Steel is a high-carbon, high-chromium tool steel, containing 12% ledeburite chromium, which provides excellent wear resistance. It is primarily used for cutting tools designed for sheet thicknesses up to 4 mm, as well as trimming and blanking dies for paper and plastics, shear cutting edges, and rotational shear edges for sheets with thicknesses up to 2 mm.

Steel Properties

D3 Steel is characterized by its high carbon content (2%) and 12% chromium, making it a robust tool steel with superior wear resistance. Typically supplied in an annealed condition to facilitate machining, D3 is hardened to a recommended hardness of 57-58 HRC after tool or die formation.

Application

HCHCR D3 steel is extensively used in cold die and tooling applications where precision in hardening and tempering is critical. It is commonly employed in the production of dies for drawing and forming, cold rolls, powder metal tooling, as well as blanking and trimming dies. Other applications include shear blades, cold die punches, ejector pins, and blanking dies for paper and plastics.