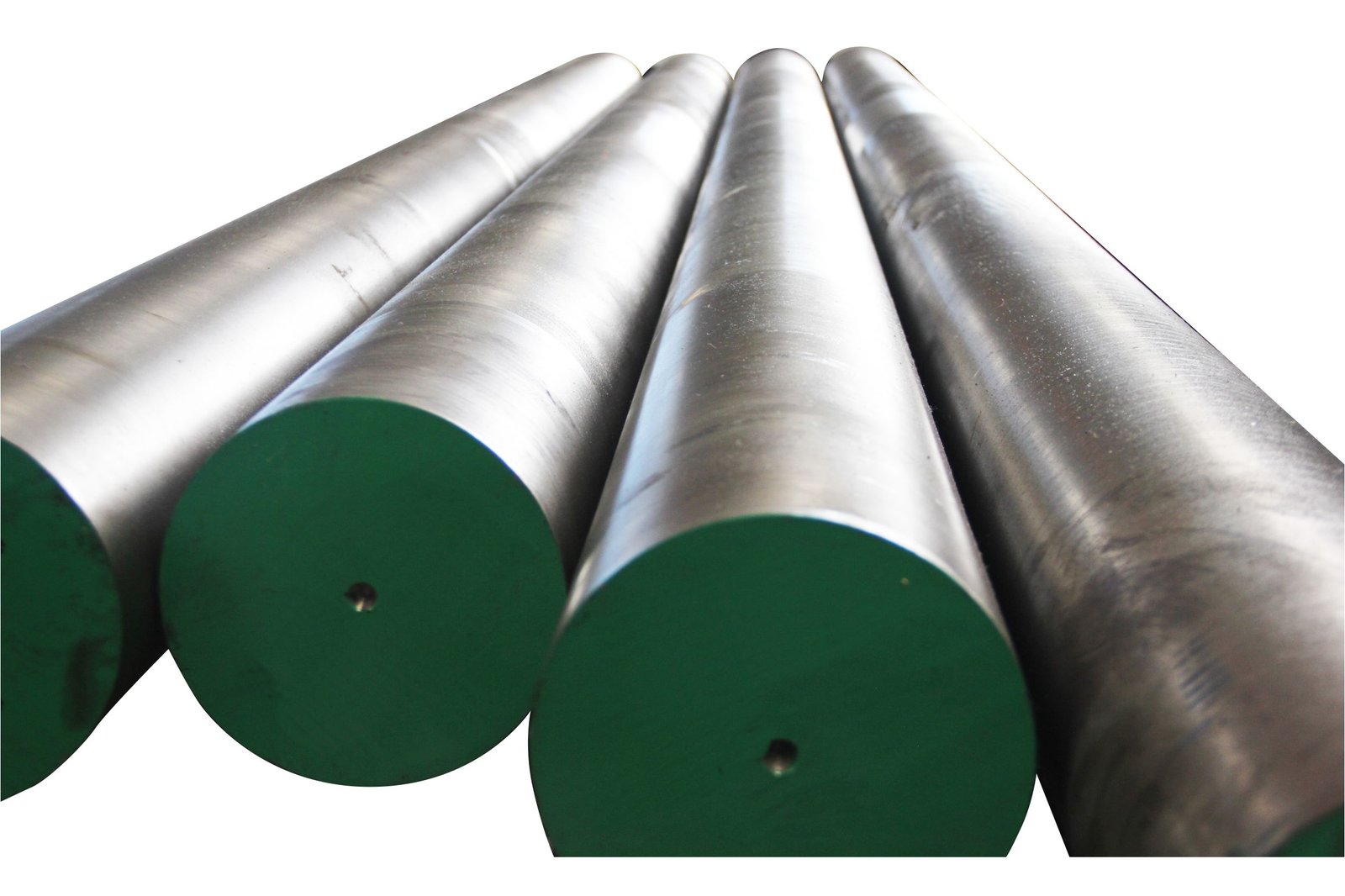

Our Products

AISI HCHCR D2 CR12MOV / DIN 1.2601

AISI HCHCR D2 CR12MOV, also known as DIN 1.2601, is a high-carbon, high-chromium cold work tool steel that provides excellent wear resistance, toughness, and hardness. It is a variation of AISI D2 steel with the addition of Molybdenum (Mo), which enhances its toughness and high-temperature strength. This steel is commonly used in industries that require superior durability and performance under demanding conditions.

AISI HCHCR D2 and CR12MOV (also known as DIN 1.2601) are both cold-work tool steels, valued for their excellent wear resistance and toughness. Below are some key properties of each:

Steel Properties

AISI HCHCR D2 CR12MOV (DIN 1.2601) is a high-carbon, high-chromium cold-work tool steel known for its excellent hardness, typically hardened to 58-62 HRC. Its exceptional wear resistance makes it ideal for tools that are subjected to constant friction and abrasion, while its good toughness, enhanced by the inclusion of Molybdenum, improves performance under shock loading conditions. Due to its high hardness, machinability can be moderate to difficult, requiring specialized tooling and processes for effective machining.

Application

AISI HCHCR D2 CR12MOV is commonly used in a wide range of demanding applications. It is ideal for the production of cutting tools, including shear blades, punches, and knives, where high wear resistance is essential. The steel is also widely used for manufacturing forming dies in cold working operations like stamping and blanking. Its high wear resistance and precision make it a popular choice for mold-making, as well as trimming and punching tools, particularly in automotive and heavy-duty industries.